GAH-201

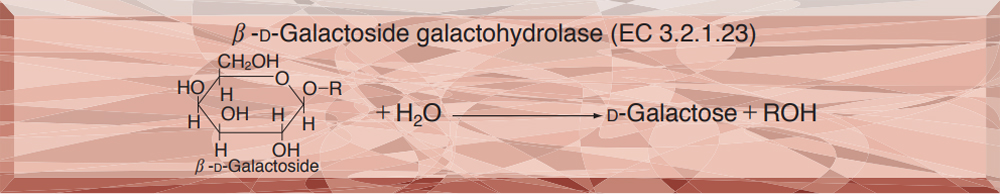

β-GALACTOSIDASE from Escherichia coli

PREPARATION and SPECIFICATION

| Appearance | White amorphous powder, lyophilized. | |

|---|---|---|

| Activity | GradeⅡ 500U/mg-solid or more | |

| Contaminants | α-galactosidase | <1×10-4% |

| α-glucosidase | <1×10-4% | |

| β-glucosidase | <2×10-3% | |

| α-mannosidase | <1×10-4% | |

| β-mannosidase | <1×10-4% | |

| proteinasee | <10mAbs/mg-P | |

| Stabilizer | Mg++ | |

PROPERTIES

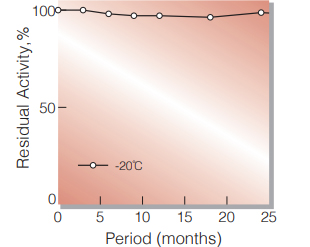

| Stability | Stable at −20℃ for at least one year (Fig.1) |

|---|---|

| Molecular weight | 540,000 1,2) |

| Isoelectric point 3) | 4.6 |

| Michaelis constants | 3.0×10-4M (o-Nitrophenyl-β-D-galactoside), 6.7×10-5M (pNitrophenyl-β-D-galactoside), 2.3×10-4sup>M (Phenyl-β-D-galactoside), 2.5×10-3M (Lactose) |

| Structure 4〜8) | The enzyme is composed of four identical subunits having a molecular weight of ca.135,000. The amino acid analysis indicates approximately 1,170 residues per subunit. E 280nm1cm (1%)=20.9 1cm |

| Inhibitors | p-Chloromercuribenzoate, lodoacetamide, heavy metal ions (Zn++, Fe+++, Cd++, Cu++, Pb++, Ag+, Hg++), lonic detergents (SDS, DAC, etc.) |

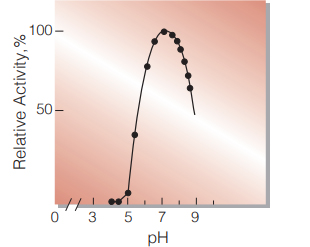

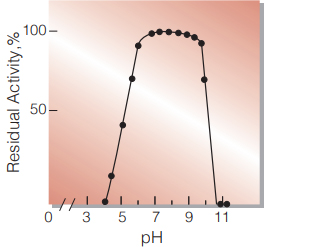

| Optimum pH | 7.0−7.5 (Fig.2) |

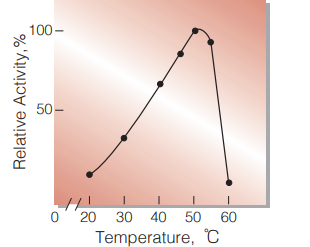

| Optimum temperature | 50−55℃ (Fig.3) |

| pH Stability | pH 6.5−8.5 (25℃, 20hr) (Fig.4) |

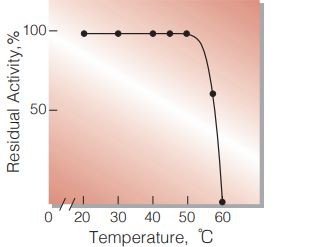

| Thermal stability | below 50℃ (pH 7.3, 15min) (Fig.5) |

| Substrate specificty | This enzyme specifically hydrolyzes β-D-galactosyl linkage (Table 1). |

| Effect of various chemicals | (Table 2) |

APPLICATIONS

This enzyme is useful for structural investigation of carbohydrates, the determination of lactose (foodstuff analysis) and as an enzyme label for enzyme immunoassay.

ASSAY

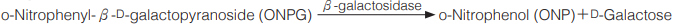

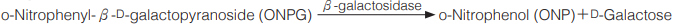

Principle

The appearance of o-nitrophenol is measured at 410nm by spectrophotometry.

Unit definition

One unit causes the formation of one micromole of ONP per minute under the conditions described below.

Method

Reagents

| A. Phosphate buffer, pH 7.3 | 0.1M (Prepare by mixing 0.1M Na2HPO4 and 0.1M KH2PO4 to reach pH 7.3 at 37℃.) |

|---|---|

| B. Mercaptoethanol solution | 3.36M[Dilute 4.0ml of 2-mercaptoethanol (14.2M) to 17ml with H2O.] (Should be prepared fresh) |

| C. MgCl2 solution | 30mM (Dissolve 610mg of MgCl2・6H2O in about 80ml of H2O and, after adjusting the pH to 7.3 with 1.0 N NaOH, fill up to 100ml with H2O.) |

| D. ONPG solution | 34mM (205mg ONPG/20ml of Reagent A)(Stable for one week if stored at 0−5℃) |

| E. Enzyme diluent | 50mM phosphate buffer, pH 7.3 contg. 1.0mM MgCl2 and 0.1% BSA |

Procedure

1.Prepare the following reaction mixture in a cuvette (d=1.0cm) and equilibrate at 37℃ for about 5 minutes.

| 2.5ml | 0.1M Phosphate buffer,pH 7.3 | (A) |

| 0.1ml | Mercaptoethanol solution | (B) |

| 0.1ml | MgCl2 solution | (C) |

| 0.2ml | ONPG solution | (D) |

| Concentration in assay mixture | |

|---|---|

| Phosphate buffer | 92 mM |

| ONPG | 2.3mM |

| Mercaptoethanol | 0.11M |

| MgCl2 | 1.0mM |

2.Add 0.1ml of the enzyme solution* and mix by gentle inversion

3.Record the increase in optical density at 410nm against water for 2 to 3 minutes in a spectrophotometer thermostated at 37℃, and calculate ΔOD per minute from the initial linear portion of the curve (ΔOD test).

At the same time, measure the blank rate (ΔOD blank) by using the same method as the test except that the enzyme diluent (E) is added instead of the enzyme solution.

*Dilute the enzyme preparation to 0.17−0.85U/ml with ice-cold enzyme diluent (E).

Calculation

Activity can be calculated by using the following formula :

Volume activity (U/ml) =

-

ΔOD/min (ΔOD test−ΔOD blank)×Vt×df

3.5×1.0×Vs

= ΔOD/min×8.57×df

| Vt | : Total volume (3.0ml) |

| Vs | : Sample volume (0.1ml) |

| 3.5 | : Millimolar extinction coefficient of ONP under the assay condition (cm2/micromole) |

| 1.0 | : Light path length (cm) |

| df | : Dilution factor |

REFERENCES

1) G.R.Graben, E.Steers, Jr.and C.B.Anfinsen; J.Biol.Chem., 240, 2468 (1965).

2) C.C.Contaxis and F.J.Reithel; Biochem,J., 124, 623 (1971).

3) K.Wallenfels and R.Weil; The Enzymes,Vol. 7, p.617 (P.D.Boyer ed.), Academic Press. New York−London (1972).

4) A.Ulmann, M.E.Goldberg, D.Perrin and J.Monod; Biochemistry, 7, 261 (1968).

5) A.V.Fowler and I.Zabin; J.Biol.Chem., 245, 5032 (1970).

6) A.V.Fowler and I.Zabin; J.Biol.Chem., 247, 5425, 5432 (1972).

7) F.Melchers and W.Messer; Eur.J.Biochem., 34, 228 (1973).

8) K.E.Langley, A.V.Fowler and I.Zabin; J.Biol.Chem., 250, 2587 (1975).

Table 1. Substrate Specificity of β-Galactosidase

-

Substrate (2.3mM) Relative

activity(%)Vmax**

(Relative value)o-Nitrophenyl-β-D-galactopyranoside 100 100 p-Nitrophenyl-β-D-galactopyranoside 14.7 13.4 Phenyl-β-D-galactopyranoside* 1.1 1.3 Lactose* 2.1 3.9 p-Nitrophenyl-α-D-galactopyranoside 0 0 p-Nitrophenyl-α-D-glucopyranoside 0 0 p-Nitrophenyl-β-D-glucopyranoside 0 0 -

Substrate (2.3mM) Relative

activity(%)Vmax**

(Relative value)p-Nitrophenyl-α-D-mannopyranoside 0 0 p-Nitrophenyl-β-D-mannopyranoside 0 0 p-Nitrophenyl-α-L-fucopyranoside 0 0 p-Nitrophenyl-β-L-fucopyranoside 0 0 p-Nitrophenyl-α-D-xylopyranoside 0 0 p-Nitrophenyl-β-D-xylopyranoside 0 0

* Liberation of galactose was measured using galactose dehydrogenase as a coupling enzyme.

**Vmax was obtained from Lineweaver-Burk plots (Vmax with o-Nitrophenyl-β-D-galactopyranoside was 1,000 micromoles of hydrolyzed substrate per min per mg-protein).

Table 2. Effect of Various Chemicals on β-Galactosidase

[This enzyme dissolved in 50mM PIPES buffer, pH 7.0(10U/ml) was incubated with each chemical at 30℃ for 30minutes. The residual activity was assayed according to the routine method described above.]

-

Chemical Concn.(mM) Residual

activity(%)None - 100 Metal salt 2.0 MgCl2 99 CaCl2 102 Ba(OAc)2 80 FeCl3 59 CoCl2 83 MnCl2 100 ZnSO4 6.2 Cd(OAc)2 4.7 NiCl2 77 CuSO4 0.9 Pb(OAc)2 1.3 AgNO3 0 HgCl2 2.0 Mercaptoethanol 2.0 99 Cysteine 2.0 102 PCMB 2.0 0.3 -

Chemical Concn.(mM) Residual

activity(%)MIA 2.0 86 NEM 2.0 95 IAA 2.0 1.4 Hydroxylamine 2.0 78 EDTA 5.0 103 o-Phenanthroline 2.0 99 α,α′-Dipyridyl 2.0 103 Borate 50 98 NaF 2.0 99 NaN3 20 98 Triton X-100 0.1% 101 Brij 35 0.1% 103 Tween 20 0.1% 103 Span 20 0.1% 107 Na-cholate 0.1% 109 SDS 0.05% 75 DAC 0.05% 0

Ac, CH3CO; PCMB, p-Chloromercuribenzoate; MIA, Monoiodoacetate; NEM, N-Ethylmaleimide; IAA, lodoacetamide;

EDTA, Ethylenediaminetetraacetate; SDS, Sodium dodecyl sulfate; DAC, Dimethylbenzylalkylammonium chloride.

-

Fig.1. Stability (Powder form)

(kept under dry conditions)

-

Fig.2. pH-Activity

37℃,15 min-reaction in BrittonRobinson buffer

-

Fig.3. Temperature activity

15min-reaction in 0.1M phospate buffer, pH7.3

-

Fig.4. pH-Stability

25℃,20hr-treatment with BrittonRobinson buffer

-

Fig.5. Thermal stability

15min-treatment with 50mM phosphate buffer,pH7.3 contg. 1.0mM MgCl2 enzyme concn.:80U/ml

活性測定法(Japanese)

1. 原理

o-Nitrophenolの生成量を410nmの吸光度の変化で測定する。

2.定義

下記条件で1分間に1マイクロモルのo-Nitrophenolを生 成する酵素量を1単位 (U)とする。

3.試薬

- 0.1Mリン酸緩衝液,pH7.3(37℃)(0.1M Na2 HPO4溶液と0.1M KH2PO4溶液を混合して37℃ でpHを7.3に調製する)

- 3.36Mメルカプトエタノール溶液〔4.0mlの 2メル カプトエタノール(14.2M)を蒸留水で17mlに希釈 する〕(用時調製)

- 30mM MgCl2溶液(610mgのMgCl2・6H2Oを約 80mlの蒸留水に溶解後,1.0N NaOHでpHを7.3に 調整し,蒸留水で100mlとする)

- 34mM ONPG溶液(205mgのONPGを20mlの試 薬Aに攪拌溶解する)

酵素溶液:酵素標品を予め氷冷した1.0mM MgCl2, 0.1%BSAを含む50mMリン酸緩衝液, pH7.3で0.17〜0.85U/mlに希釈する。

4.手順

1.下記反応混液をキュベット(d=1.0cm)に調製し,37℃ で約5分間予備加温する。

| 2.5ml | 0.1Mリン酸緩衝液,pH7.3 | (A) |

| 0.1ml | メルカプトエタノール溶液 | (B) |

| 0.1ml | MgCl2溶液 | (C) |

| 0.2ml | ONPG溶液 | (D) |

2.酵素溶液0.1mlを添加し,ゆるやかに混和後,水を対照 に37℃に制御させた分光光度計で410nmの吸光度 変化を2〜3分間記録し,その初期直線部分から1分 間当りの吸光度変化を求める(ΔODtest)。

3.盲検は酵素溶液の代りに酵素希釈液(1.0mMの MgCl2を含む50mMリン酸緩衝液,pH 7.3)を0.1mlを 加え,上記同様に操作を行って1分間当りの吸光度変化 を求める(ΔODblank)。

5.計算式

-

U/ml =

-

ΔOD/min (ΔOD test−ΔOD blank)×3.0(ml)×希釈倍率

3.5×1.0×0.1(ml)

| = ΔOD/min×8.57×希釈倍率 | |

| 3.5 | : o-Nitrophenolの上記測定条件下でのミリ モル分子吸光係数(cm2/micromole) |

| 1.0 | : 光路長(cm) |

CONTACT

お問い合わせ-

各種製品に関するご質問・ご相談はこちらよりお問い合わせください。